Search for topics or resources

Enter your search below and hit enter or click the search icon.

August 7th, 2024

3 min read

Safety is a top priority wherever you go. Whether you are driving in your car, shopping in a mall, or even walking down the street, safety measures are put in place to ensure you feel secure.

One of the most important places to feel safe is at your job. If you don’t feel safe at a place you go to every day, it can create an unsettling environment.

Imagine working on the production line in a manufacturing facility surrounded by machines. The constant movement in the facility can pose potential safety hazards. However, if your company has implemented safety measures to protect you, your colleagues, and the facility, you can feel safe.

Safety measures in a manufacturing facility can involve various components, but some of the most crucial are those that prevent electrical fires or shocks. These components are the SCCR and KAIC ratings implemented in electrical systems.

At ASG, we aim to promote electrical safety in all the products we create for our customers, so we know a thing or two about safety protocols. For us to design systems properly, our customers must ask utility sources how much available fault current is coming from the generation source.

Let’s dive into the importance of SCCR and KAIC ratings in electrical equipment and how they impact a manufacturing facility, relating to standards and regulations.

To fully understand the importance of SCCR and KAIC ratings in your electrical equipment, we first need to learn what they are.

SCCR, or Short Circuit Current Rating, is the maximum fault current a piece of equipment can safely withstand without damage. It is most often used as a comprehensive rating for an entire assembly and its components.

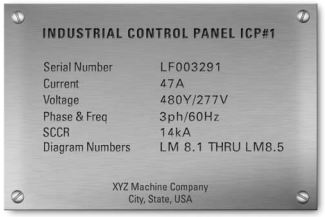

In simpler terms, SCCR is the defined fault current that the entire assembly can withstand before failing. This rating is listed in kiloamperes on the machine so that users are aware of the maximum current it can handle.

Source: AWC, Inc.

KAIC, or Kilo-Ampere Interrupting Capacity, is the maximum fault current an overcurrent protective device (OCPD) can safely interrupt before it is damaged. KAIC ratings are specific to OCPDs and are not for the entire electrical assembly because of their ability to interrupt the flow of current.

Simply put, KAIC ratings measure a circuit breaker or fuse’s ability to withstand a short circuit or overload. As the KAIC tasting gets higher, the amount of electrical surges that can be handled safely increases.

Source: Electrical License Renewal

These two ratings are related because they must coincide. Engineers must ensure that the KAIC rating of a device is less than or equal to the SCCR listed on the equipment. The SCCR rating, established by the manufacturer, is challenging to alter once set. Without the proper KAIC and SCCR ratings, there could be a risk of fire or other potential harm.

Keeping manufacturing facilities safe is crucial for running a productive facility. Without safety, the production line would not be able to operate efficiently.

So, why are SCCR and KAIC ratings so important? Let’s dive into the important impacts they have on the facility.

Properly rated SCCR and KAIC help prevent electrical shock, fire, and other hazards by ensuring equipment and protective devices can handle fault conditions.

These ratings also ensure compliance with safety standards set by regulatory bodies like the National Electric Code (NEC) and the Occupational Safety and Health Administration (OSHA).

Correct ratings prevent equipment from being damaged during short circuits and ensure that faults are interrupted safely. Properly rated systems can handle fault conditions, minimizing the risk of unexpected downtime due to equipment failure.

Following SCCR and KAIC ratings ensures compliance with local, national, and international electrical codes, avoiding legal issues and potential fines.

The 2020 NEC update requires clear marking of SCCR on equipment to note the maximum short circuit current, promoting transparency and adherence to regulations. UL certifications, such as UL508A, also work in conjunction with SCCR to ensure the safe operation of electrical equipment.

Ensuring SCCR and KAIC are matched properly from the beginning helps in selecting compatible components, leading to efficient system design. System requirements are always subject to change, so building an appropriate factor of safety is essential.

Properly rated SCCR and KAIC improve efficiency under normal and fault conditions. Reduced downtime and increased operational efficiency ultimately enhance productivity and profitability.

All of these aspects are extremely crucial in ensuring a fully operational facility. And, all of these impacts come back to the same main idea: SCCR and KAIC are essential to ensure this fully operational facility.

Even if you are not directly working with the electrical equipment that SCCR and KAIC ratings are implemented on, it is important to understand their significance. The main goal of SCCR and KAIC ratings is to make your workplace safer. When these ratings are properly implemented, they ensure safety in your electrical equipment, providing peace of mind.

At ASG, we manufacture control panels, enclosures, switches, and more that are used in manufacturing facilities. When these are rated for SCCR and KAIC, it is crucial to ensure their installed environment is safe. If you have any questions about SCCR or KAIC and would like to learn more about the rating process, reach out to us today!

Topics: